Do NOT Touch the Pipes

In which we take a tour and ask way too many questions.

April 10, 2018

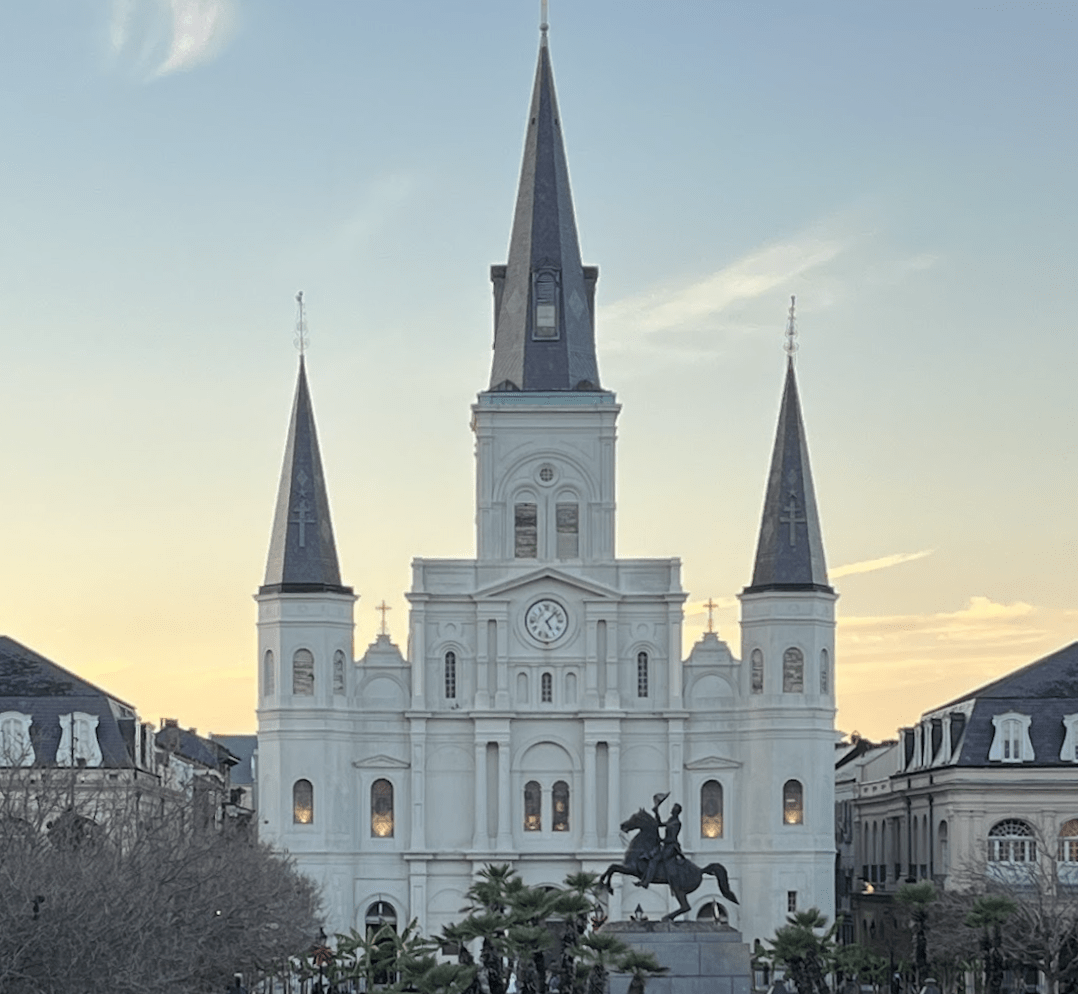

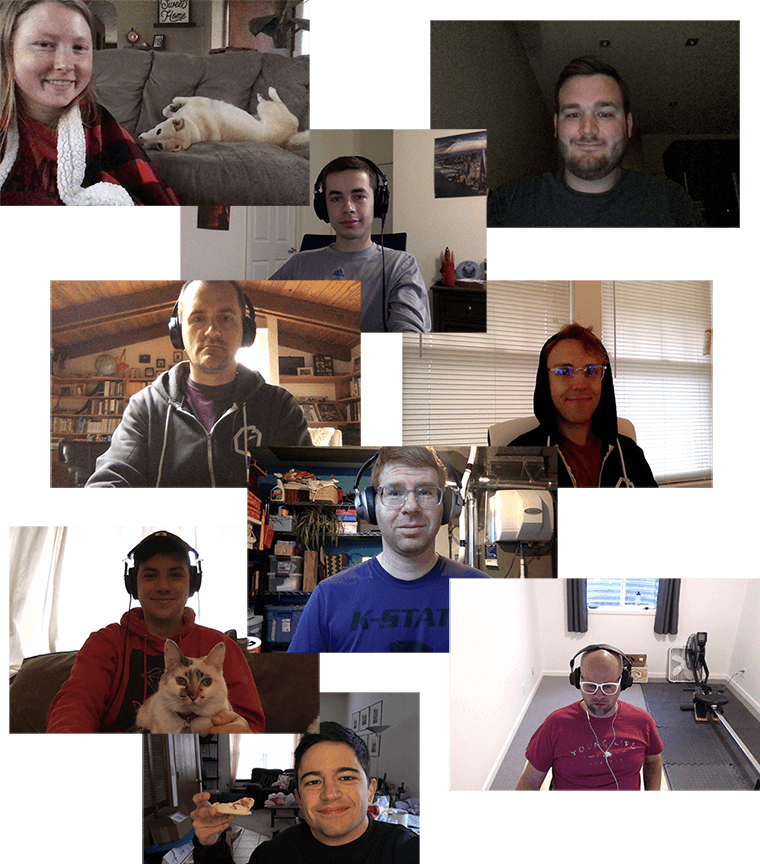

Once a month at Brand New Box, we take a break from staring at computers and do something to celebrate the achievements of the past month. This month: a factory tour of one of the country’s biggest manufacturers of pipe organs, The Reuter Organ Company.

This was super fascinating - in one unassuming building, they make entire gigantic pipe organs for churches and concert halls all over the world.

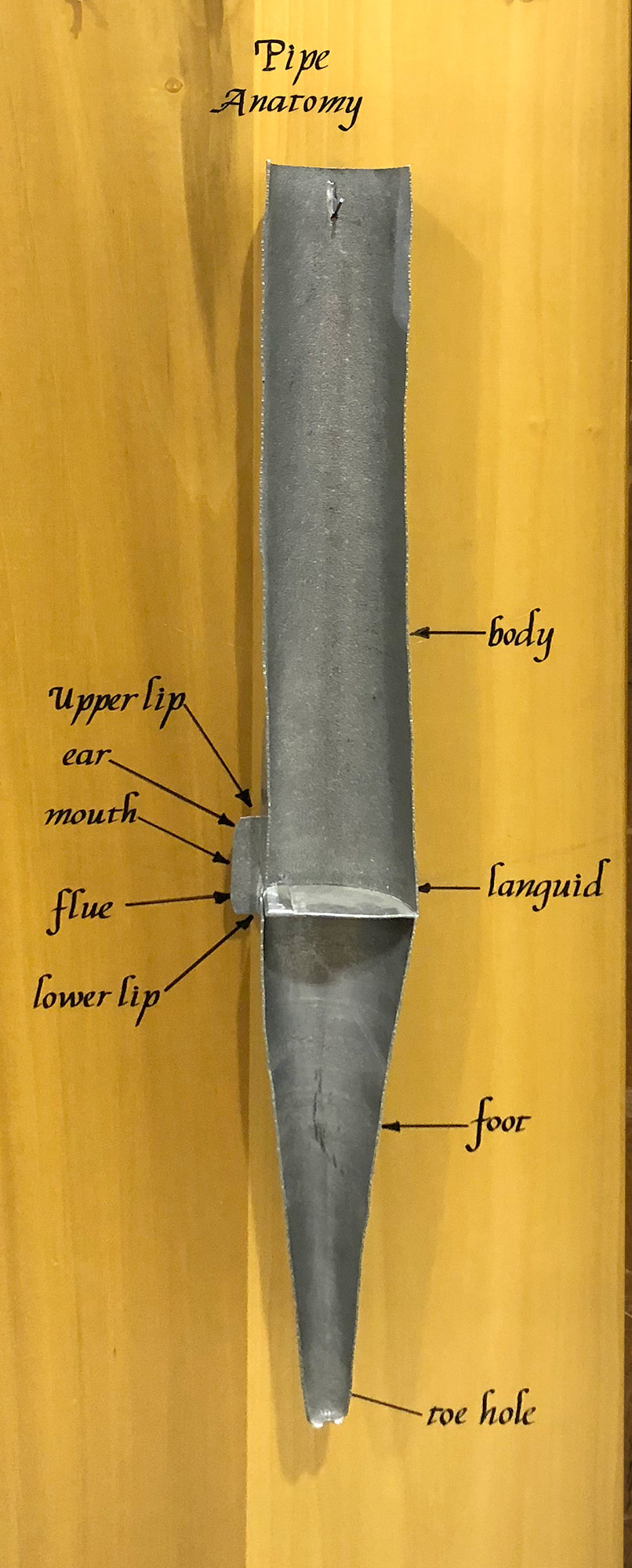

The tour starts with Jeff giving us an overview of some portfolio pieces, and a quick primer on organ anatomy. It was at this point in the tour it became clear that we were going to be asking a lot more questions than Jeff expected.

Reuter makes all the parts of an organ except the stopper knobs and the electronics - of which there are surprisingly few.

Fun fact: new organ installations are given *Opus numbers*, just like a composer numbers his sonatas.

Organs are complicated.

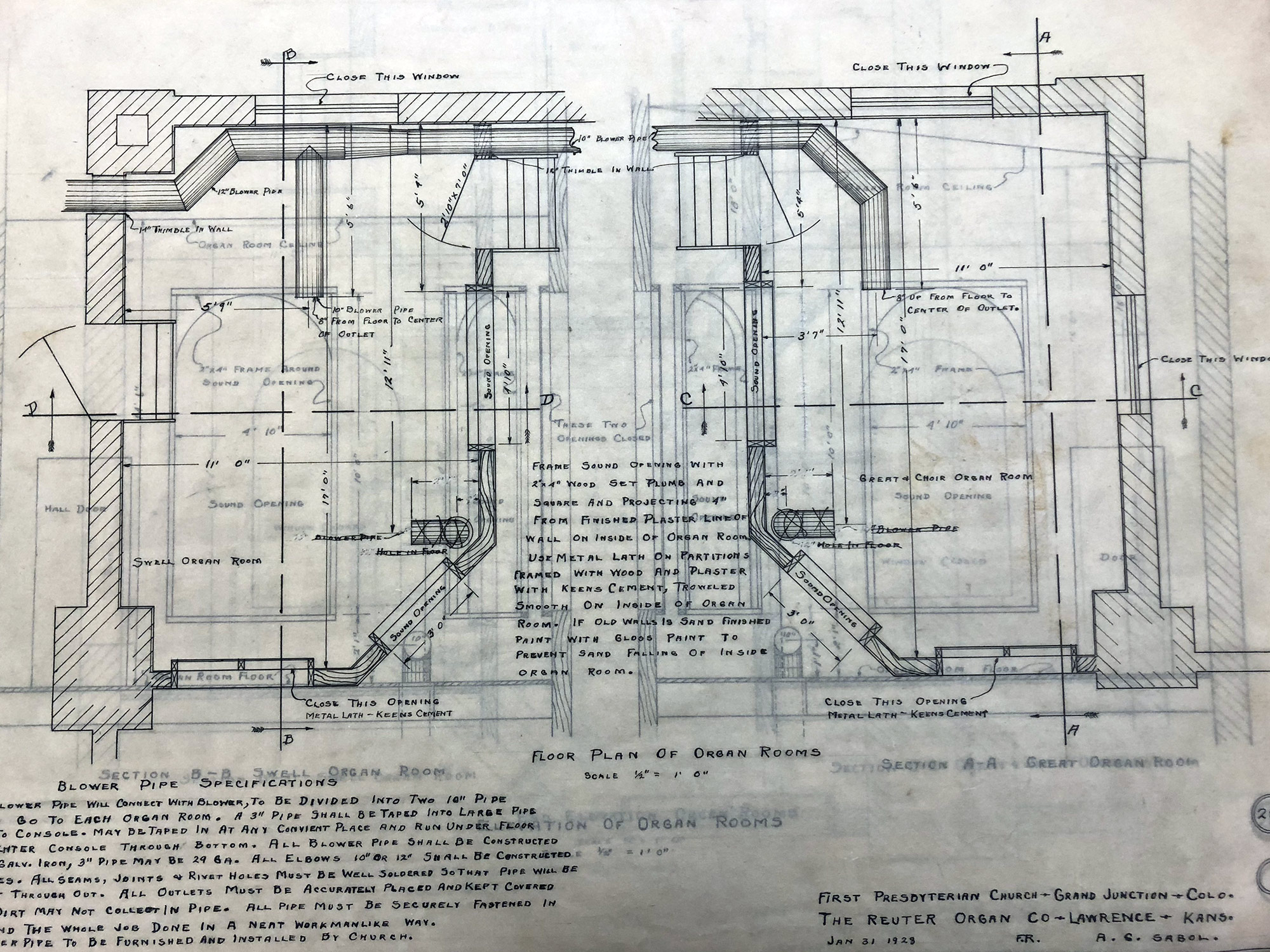

From there, we got saw the engineering room, which is mostly filled with long drafting tables and drawings of their organ setups. They’ve got the paper drawings on file in this room from the last hundred years of organs.

Number of computers seen thus far: zero.

They’re pretty amazing. And not digitized yet!

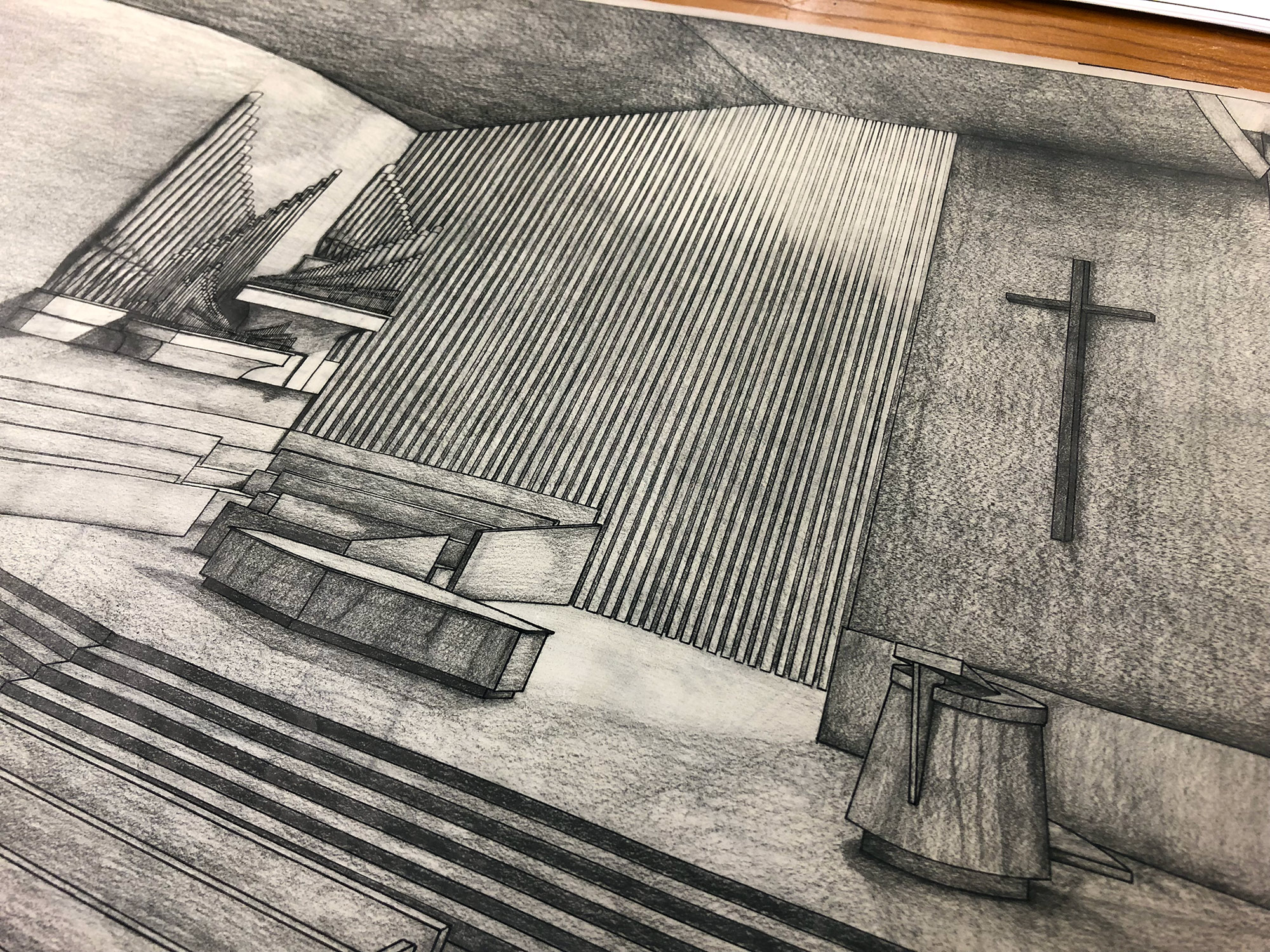

In addition to the technical drawings, there are renderings from the other projects too. Pencil renderings!

From the engineering room, we hit the lunch room, which has two small working organs for workers to play. These are small potatoes compared to the big church installs, but still would take up a lot of room in your house.

There were very few safety warnings through this tour, but we did learn one thing very clearly:

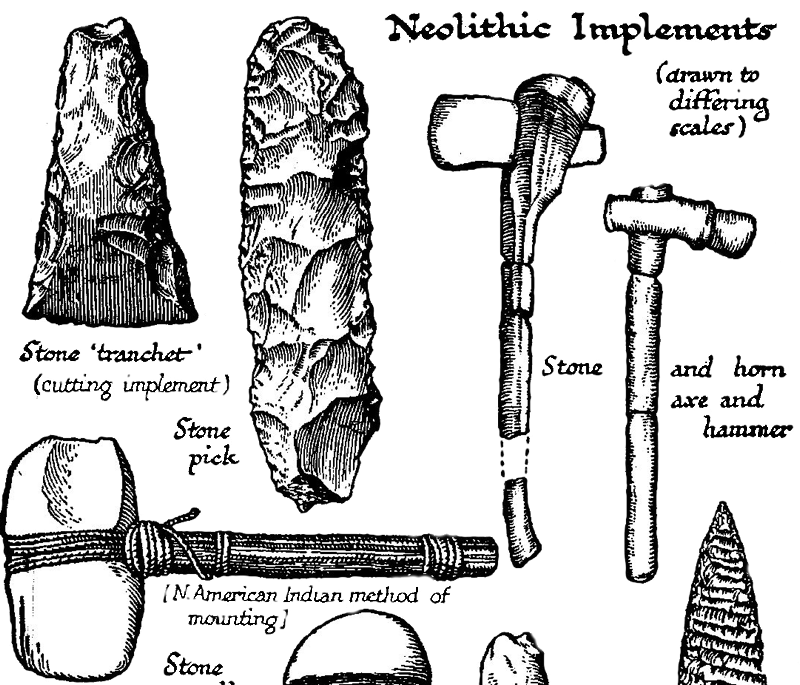

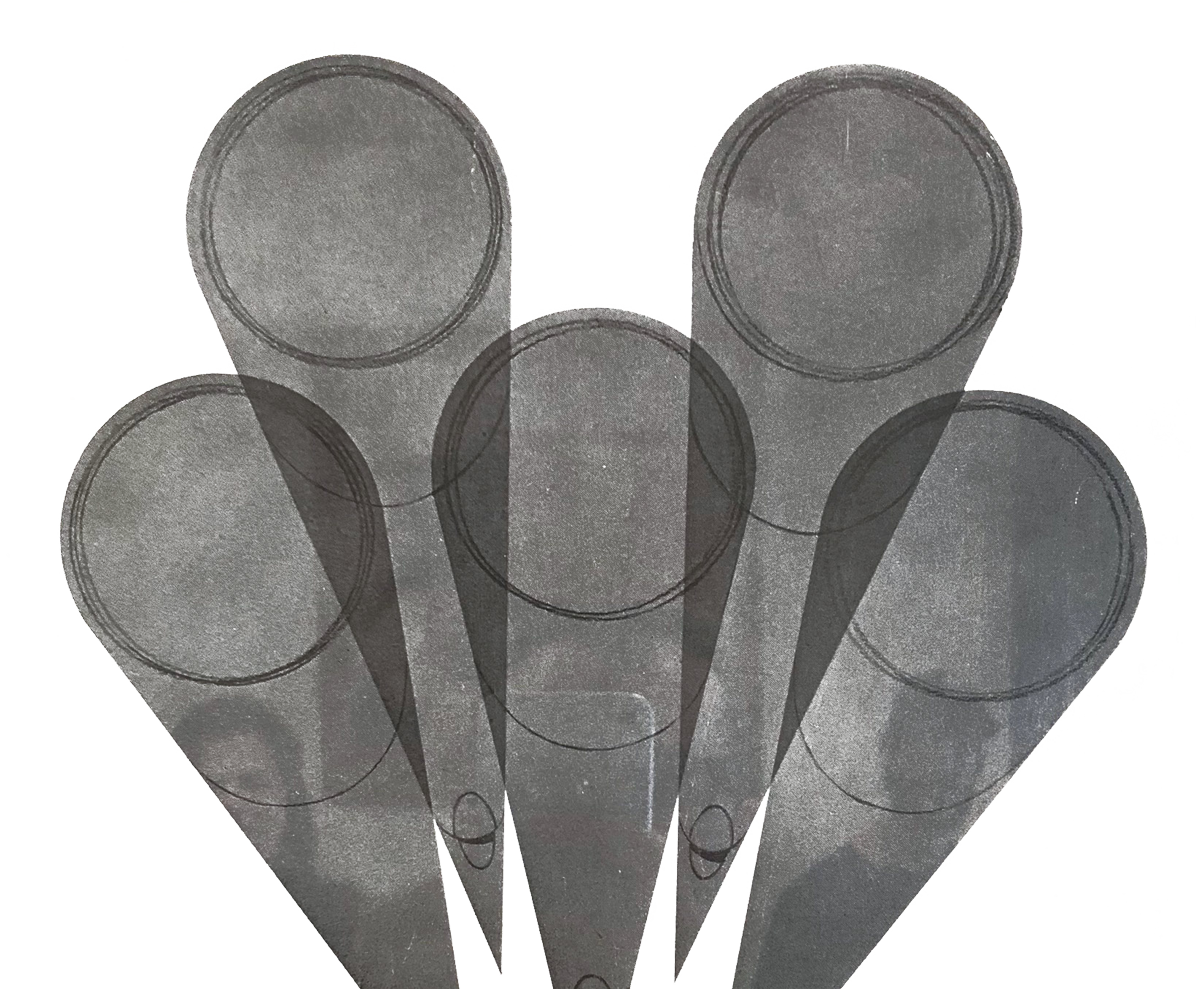

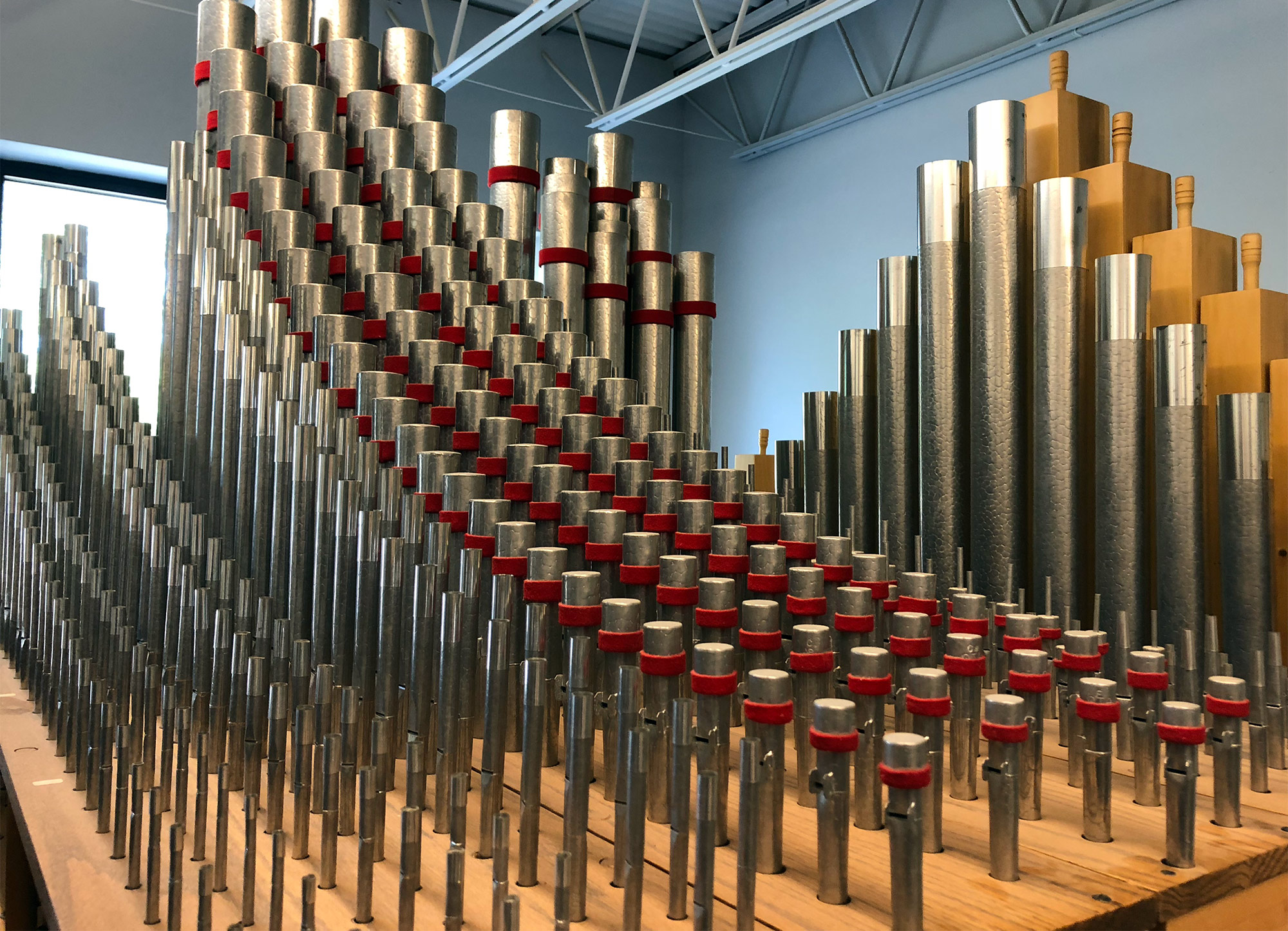

The pipes themselves are always stunning to look at, and arranged in these graceful curves (see this justifiably famous cryptonomicon quote). Notice that speckled-looking metal surface on the pipes to the right? We’ll learn more about that later.

The pipes have adjustable caps on them, so the height of the air column inside (and thus the note they produce) can be tuned. Pipes have different sizes to hit different notes of course, but the material used also produces different timbre. Organists swap out and mix different pipes and tones using the stops.

There are a LOT of stops.

Also, this is where the phrase comes from: when you let turn on ALL the sounds your organ can make, you're PULLING OUT ALL THE STOPS.

Past the break room we get into the real production area, and we all gasped: it’s the woodshop of your dreams.

Turns out making organs involves a lot of fine casework.

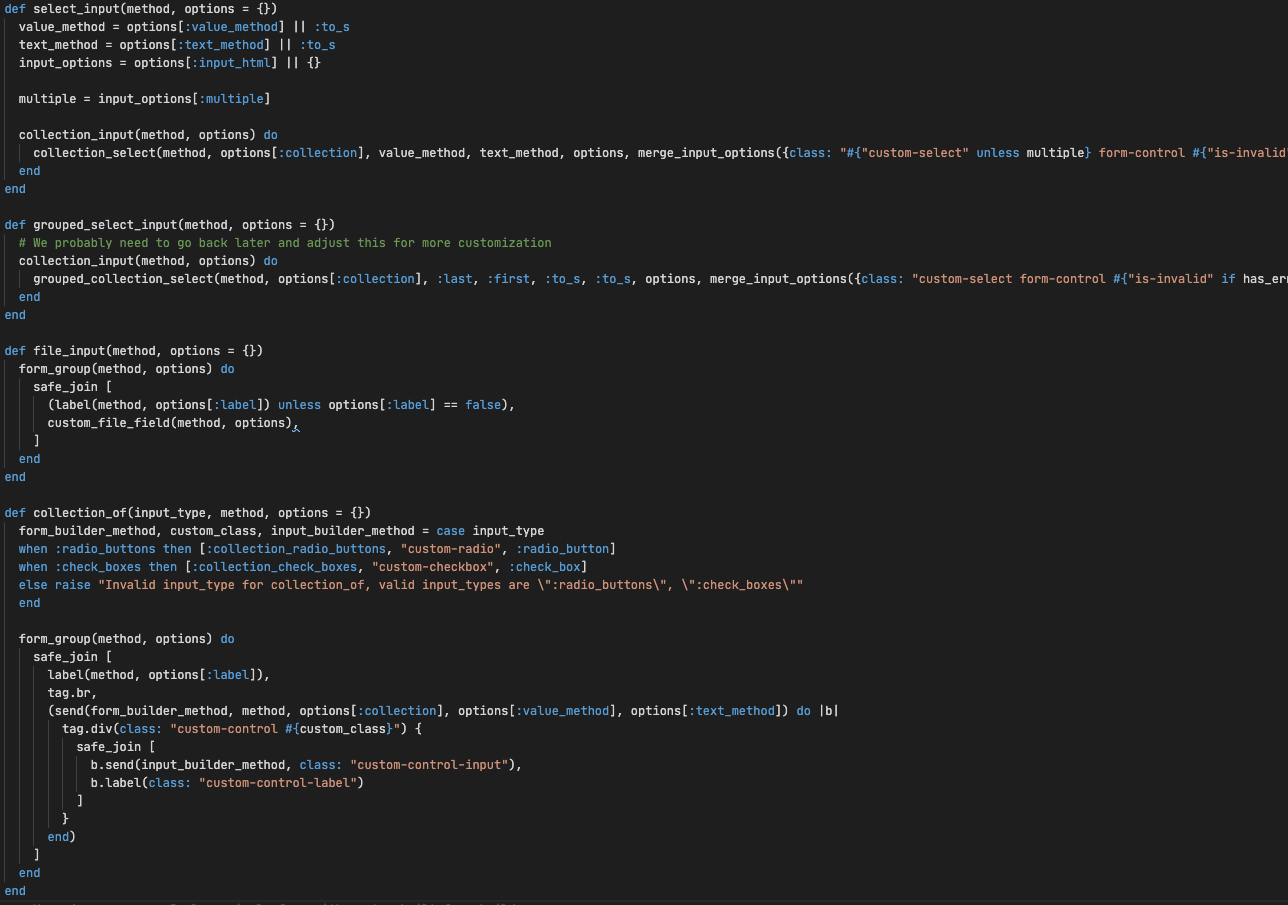

The only PC computer we saw in this whole tour was claimed to be a 286 that ran this CNC bed. Jeff says they use the CNC machine for some of the detailed casework and custom decorative elements (like on the wall here, top left), but that’s about it.

Remember that pebbled metallic surface that some of the pipes have? They literally make that alloy here in this small forge. Ingots of tin and zinc go in, the metals are mixed, and they pour it out in rough sheets, about 2’ x 8’.

The rough sheets are smoothed out on this lathe(??), and the trimmings go back to the forge. The sheet metal is cut out into shape using handmade templates like these; they’ve got templates for every size ever produced, going back to 1917.

The actual valves involved in letting air in and out of the pipes are made of leather (!), a thin, stretchy leather that can be cow, goat, sheep, or kangaroo. Here below, the white circles are felt stoppers, and the light brown circles are stretchy leather. The organs also use small leather hinges in some places.

Outside the woodshop, there’s a room where the pipes are prepped to be voiced. We got to actually touch the pipes (DO NOT TOUCH THE PIPES) here, and blow them like giant whistles. We might have dropped a couple.

Helpful!

John here ‘voices’ the pipes; that means he’s the guy who carefully cuts the mouth into the pipes, and adjusts them all to have consistent pitching and timbre. He’s worked at Reuter for 34 years, and been voicing for around 25. The pipes are tuned here, but then they must be adjusted in situ after they’ve been installed, a process that can take weeks for a large organ. And because the pipes all need to be tuned together, it’s a job that you can’t just throw more people at - no mythical man-month here.

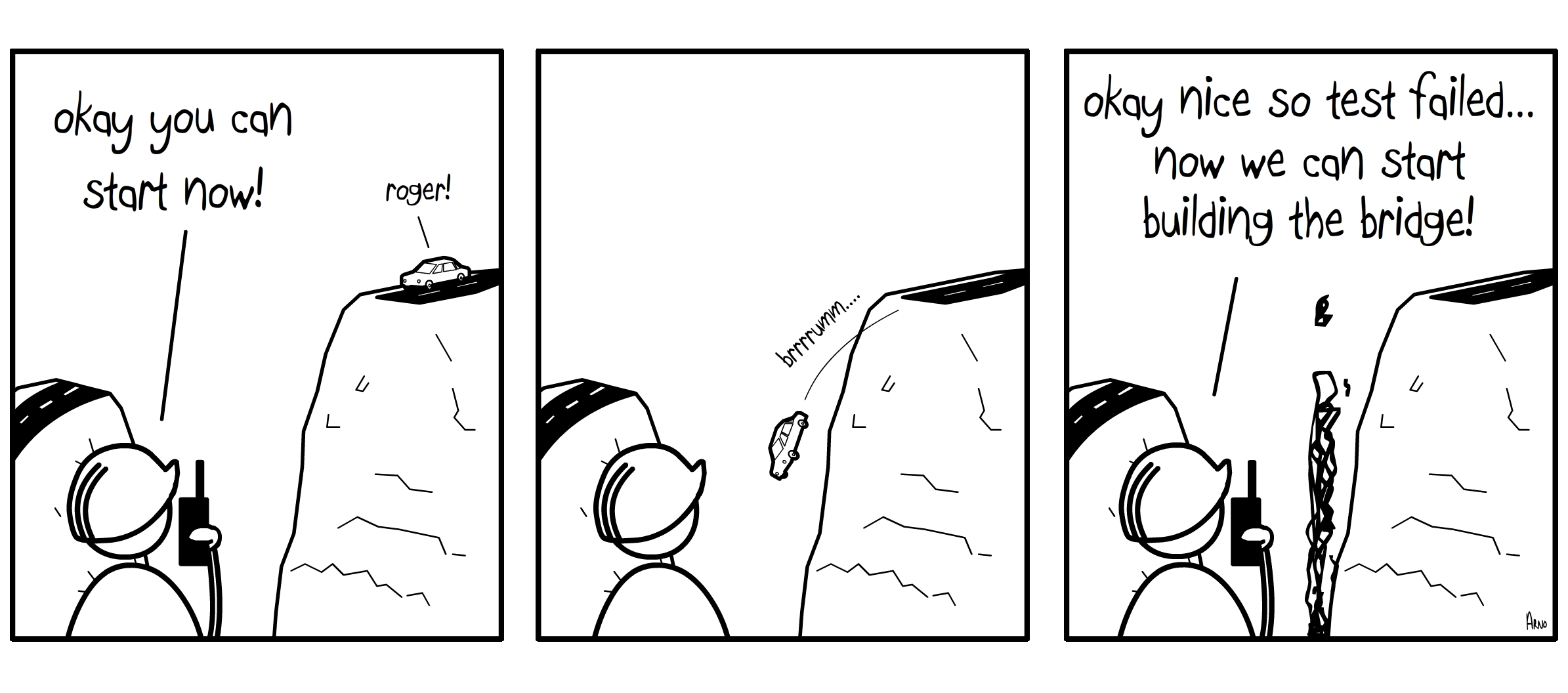

The last stop on the tour: assembly and shipping. The entire organ is assembled in this big area first, including for the first time the electronic components. They test and play it for the first time, and then when they’re satisfied, they disassemble the whole thing and prep it for shipping. Behind us in the photo are pipes carefully wrapped in foam, ready for shipment.

I loved this sign we noticed on the way out, both for its canny advertising and its very Mad Men-era aesthetic.